Primitive technology with survival skills Ancient Bricks ...

Dec 09, 2017· This is our next video on primitive technology Ancient Bricks. Next to video 1 in this video, we have played a lot of Ancient Bricks to carry out .

WhatsApp)

WhatsApp)

Dec 09, 2017· This is our next video on primitive technology Ancient Bricks. Next to video 1 in this video, we have played a lot of Ancient Bricks to carry out .

The ground granulated blast furnace slag (GGBFS) is a byproduct of iron manufacturing which when added to concrete improves its properties such as workability, strength and durability. This material is obtained by the heating of iron ore, limestone and coke at a temperature about 1500 degree Celsius.

Open hearth steelmaking means the pig iron, more iron ore and limestone go into an open hearth furnace. The charge is heated to about 1,600 degrees F. The limestone and ore form another type of slag, which floats to the surface, carrying with it other impurities (including carbon) from the pig iron.

May 05, 2017· SCMs in Concrete: Slag Cement. National Precast Concrete Association / Precast Magazines / Precast Inc. Magazine / 2017 – MayJune / SCMs in Concrete: ... Heating iron ore in excess of 2,700 degrees Frenheit melts the metal and separates the pure iron from the impurities in the ore. Together, the impurities and the other materials in the ...

The characteristics of bricks made from steel slag were investigated in this research. Slag addition was shown to reduce the required firing temperature. When the firing temperature was greater than 1050 °C and the slag addition less than 10%, the bricks met ROC national standard CNS 3319 thirdclass brick .

Nov 13, 2016· I emptied the steel output inventory by stopping the iron ore train to the steelmill, and transportet all steel out of the steel mill. when the steel inventory was empty the recepie changed from 1xsteel to 2xsteel + 1x slag. But after 1 year, it changed back, although the slag was transported away steadily. Exactly.

During the early 20th century, iron ore slag was also ground to a powder and used to make agate glass, also known as slag glass. Modern uses. Ground granulated slag is often used in concrete in combination with Portland cement as part of a blended cement. Ground granulated slag reacts with a calcium byproduct created during the reaction of ...

A blast furnace is a special type of furnace for smelting iron from furnaces are very large. They can be up to 60 metres (200 ft) tall and 15 metres (49 ft) in blast furnace is the biggest chemical furnaces are also called high ovens.. A blast furnace is usually built with a steel case and bricks made of magnesium oxide or other refractory material inside ...

Sep 09, 2015· "Slag" is the glasslike byproduct left over after a desired metal has been separated from its raw ore. Slag is usually a mixture of metal oxides and silicon dioxide. However, slags can contain ...

In making brick on a small scale, firing is a periodic operation wherein the bricks are placed in the kiln, the fire started and heat developed, and then, after several days of firing, the fuel is cut off from the fire and the entire kiln and its load are allowed to cool down naturally.

Apr 28, 2014· How A Blast Furnace Works The purpose of a blast furnace is to chemically reduce and physically convert iron oxides into liquid iron called "hot metal". The blast furnace is a huge, steel stack lined with refractory brick, where iron ore, coke and limestone are dumped into .

Supplementary cementitious materials (SCM) such as pozzolans (such as powerplant ash) and slag (a byproduct of iron smelting) are sometimes added to the cement mixture as well. Pozzolans are materials that exhibit cementlike properties when combined with lime. When it comes to ensuring proper proportions, making concrete is a lot like baking.

Sep 22, 2017· (Turn on captions [CC] in the lower right corner for more information while viewing.) I made a brick mold that makes bricks 25 x x cm .

They are inexpensive, simple to make, environmentally friendly, and used all over the world to make lowcost homes and fireproof buildings. Before you begin, make sure you clear out a dry area for making bricks. They could take several weeks to dry and need to be protected from the rain. Follow these simple steps to make your own mud bricks.

To make steel, iron ore is first mined from the ground. It is then smelted in blast furnaces where the impurities are removed and carbon is added. ... the furnace itself is a huge steel shell almost cylindrical in shape and lined with heatresistant brick. ... The tapping of iron and slag is the major factor permitting additional materials to ...

Waste slag as alternative raw material in the cement production . Ferrous slag is produced by adding slagging agents such as limestone or dolomite and/or fluxing materials to blast furnaces and steel furnaces to strip the impurities from iron ore, steel scrap, and other iron or steel input feeds.

Mar 03, 2017· It is fully called as Groundgranulated blastfurnace slag (GGBS or GGBFS) and is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is ...

In this circumstance, this analysis observes on utilizing iron ore tailings and slag sand as a substitution for clay or natural sand for the construction of steady geopolymer obstruct. Furthermore, in this analysis, geopolymer is utilized as a binder rather than cement.

Shropshire History. Ironmaking . Processes. Return . to Index. Iron. Iron Properties. Iron Making. Iron Sites. Ironmasters. Coalbrookdale Company . Bloomery Process. This was a simple method used from the Iron Age to medieval times where iron ore and charcoal were placed in a small furnace.

May 09, 2018· It is a byproduct from the blast furnace which is used to make iron. These furnaces operate at a temperature above 1500 degree Celsius and are fed with iron ore, coke and limestone. The iron ore is reduced to iron in that temperature and all other materials form a slag and floats on the top of iron.

Jan 27, 2020· Slag is a byproduct of metal smelting, and hundreds of tons of it are produced every year all over the world in the process of refining metals and making other industrial byproducts, slag actually has many uses, and rarely goes to waste. It appears in concrete, aggregate road materials, as ballast, and is sometimes used as a component of phosphate fertilizer.

Immediately in front of the tuyeres is the combustion zone, the hottest part of the furnace, 1,8502,200°C, where coke reacts with the oxygen and steam in the blast to form carbon monoxide and hydrogen [as well as heat] and the iron and slag melt completely. Molten iron and slag collect in the furnace hearth.

Jul 17, 2018· That other video had the ore on a pot not in it and it produced slag with mm sized spheres of iron. I mixed the ore with charcoal powder (reductant) and ash (flux). I did a smelt yesterday in a tall natural draft furnace using an ore brick on a grate and it produced slightly larger beads of iron but still not a great amount.

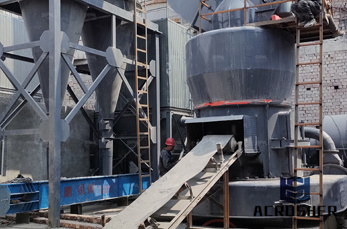

Slag Bricks. The slagbrick industry may be considered to be a specialized branch of the slagcement industry, but a wider range of slags may be used. The manufacture includes bricks, pipes, and other special shapes, and the details of practice vary considerably in different works.

WhatsApp)

WhatsApp)