ball mill rpm optimal

M MILLS Roll Jar Mills MRCLAB. Speed range: up to 600 rpm. ... RJM103, Large Ball Mill3 Adjustable Roller ... Our jar mills are ideal for RD, small .

WhatsApp)

WhatsApp)

M MILLS Roll Jar Mills MRCLAB. Speed range: up to 600 rpm. ... RJM103, Large Ball Mill3 Adjustable Roller ... Our jar mills are ideal for RD, small .

6 L Vertical Small Lab Planetary Ball Mill Machine Portable Ball Grinding Mills . 1. Description. Planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and . small volume hightech material production. The instrument has small volume, complete function, high efficiency and low ...

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to ...

Many types of mills providing high shear force are generally adopted machine in cosmetic industry. Among these, the three roll mill is the preferred mill since its advantages of uniformly applied shear force on the whole ingredients and adjustable product capacity by different designed size.

Innovative design features, including variable speed control (can accommodate a large range of jar sizes), inverter controlled drive for high electrical efficiency, dropin slots for quick roller bar changeout, easily accessible roller shaft bands and wrapped in a beautiful Stainless Steel shroud making Peter Pugger''s Single Ball Mill the first choice for smallscale to largeproduction ...

Mill speed critical speed mill speed no matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operationoo low a. ... Optimizing the ball mills rpm make sure the whole roller assembly now looks as it originally did, and ...

The MSKSFM3 (Updated since 7/17/13) is a compact high speed vibrating ball mill for making small quantity of powder samples at easy and fast with improved vibration design. It has higher impact energy created by three dimensional movement, rotation, vibration and oscillation with frequency up to 1200 cycles per minute with two year warranty.

Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs. Ball Mill Rpm Sale cmandiorg. ball mill 100 rpm for sale tvpdcollegein second hand ball mills sale ball mill 100 rpm for sale Cement mill Wikipedia A ball mill is a horizontal cylinder .

Rotational speed: 400 rpm. Ball mill is a necessary equipment for mixing and fine grinding of powders in new product development and small volume ... The FAM product range includes impact mills, roller mills, hammer mills, ball mills and rod mills ... They can perform a lowcost particle size reduction to submicron range. The instrument can ...

Sep 29, 2015· There is a vast range of mill types available commercially and the choice of mill is based on a variety of factors, ... Fig. 5 shows the PSD of samples of γAl 2 O 3 milled using the PBM at 700 rpm. The characteristic sizes at different mill times are shown in ... rendering the planetary ball mill as less suitable for size reduction of ...

Jan 11, 2019· MOREBall Mill Presentation ScribdApr 22, 2009 The rpm of mill The difference in speed between balls INLET TUBE mostly for wet mills INLET CHUTE with fresh air flap for mill .

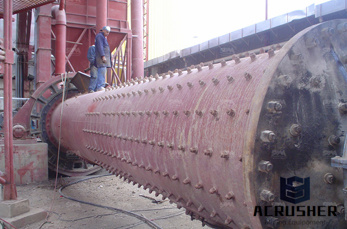

Ball mills are a fundamental part of the manufacturing industry in the USA as well as around the world. Ball mills crush material into various sizes and extract resources from mined materials. Pebble mills are a type of ball mill and are also used to reduce the size of hard materials, down to 1 micron or less.

Oct 19, 2006· What it is the optimun speed for a ball mill ? posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use in a ball mill (the pvc cylinder that i use, left of the shafts). With the motor i will use a 40 mm pulley, because i have a 50 mm driven pulley, in one of my two shafts.

A roller mill uses significantly less horsepower than a hammermill of the same capacity but will not work on soft or fibrous materials. A hammermill may be used to grind ingredients to very small particle sizes, but the particle size range is wider and creates significantly more very fine particles than a roller mill.

Rotational speed: 300 rpm 360 rpm Output: 85 kg/h. Powerful precrushing The FRITSCH PULVERISETTE 25 is our heavy duty Power Cutting Mill for fast, reproducible precrushing of dry, soft to mediumhard or fibrous materials and plastic with a feed size of 120 x 85 mm ...

Apr 09, 2015· Ball mill is a versatile grinding mill and has a wide range of applications. The mill can vary in size from small batch mills up to mills with outputs of hundreds of tons per hour. They are the most widely used of all mills. Roller mills. Roller mills are basically of two distinct types.

Innovative design features, including variable speed control (can accommodate a wide range of jar sizes), inverter controlled drive for high electrical efficiency, dropin slots for quick roller bar changeout, easily accessible roller shaft bands and wrapped in a beautiful Stainless Steel shroud making Peter Pugger''s Double Ball Mill the first choice for smallscale to largeproduction milling.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

SMALL C. I. W. BALL MILL. The CIW is a Small Ball Mill that''s belt driven, rigid bearing, wet grinding, trunnion or grate discharge type mill with friction clutch pulley and welded steel shell. The 7 and 8 foot diameter mills are of flange ring construction with cut gears while all other sizes have cast tooth gears.

150. 200 kg*. 300 kg*. 600 kg*. 320 x 800 x 960. 450 x 900 x 1160 ... Wide speed range, adjustable from 6000 to 18000 rpm, fine control for sample feed. ..... The DM 200 disc mills are mainly used for preliminary and fine grinding of medium.

Size(Inclined hole chamfer size x length) 4 x Countersink and Deburring Tools. 5 out of 5 stars. 1 product rating 1 product ratings ... 2 PC 1/2" X 45?. 1/2" X 60?. DOVETAIL CUTTER SET HIGH SPEED STEEL HSS MILLING. The ideal cutter for milling dovetails, right hand cutting. ... 5pcs 2 Flute Ball Nose End Mills CNC Router Bit Milling ...

Ball Mill Operating Speed But the mill is operated at a speed of 15 rpm Therefore, the mill is operated at 100 x 15 307 = 4886 % of critical speed If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [04886 2 p] x .

High Speed Roller Mill For Powder high speed wet ball mill grinding machine Mini Wet Grinder . high performance mill food powder machine machine roller grinding mill with high cost. Roller mill Wikipedia. Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or .

Aside from common ball mills there is a second type of ball mill called a planetary ball mill. Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes. A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled ...

WhatsApp)

WhatsApp)