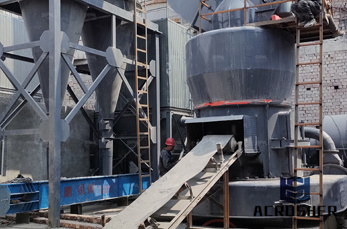

Small Grinding Mill (Ball Mill) YouTube

Jan 09, 2018· A grinding mill which operates as either a rod mill or a ball mill with a 20 to 300 lbs (10 to 150 kg)/hour capacity. Complete with feed hopper and classification system.

WhatsApp)

WhatsApp)

Jan 09, 2018· A grinding mill which operates as either a rod mill or a ball mill with a 20 to 300 lbs (10 to 150 kg)/hour capacity. Complete with feed hopper and classification system.

Ball Mill Zhengzhou Shibo Mechanical Engineering co,ltdThe Hotsale Models and Capacity of Ball Mill 900 × 1800, 1200 × 2400, 1500 × 3000, 1830 × 6400, 2

Ball mills have been successfully run at speeds between 60 and 90 percent of critical speed, but most mills operate at speeds between 65 and 79 percent of critical speed. Rod mills speed should be limited to a maximum of 70% of critical speed and preferably should be .

Yes the mill is almost running with double its capacity (Rated 30TPH, running with 55 TPH), earlier we used to have seal wiper and SS seal ring. In this course seal wiper didn''t give good life and within a week the leakage used to start again, hence we changed the MOC of .

Nov 13, 2016· Xq80. Stew rolling mill to produce grinding steel ball from 40 mm to 80mm. Capacity 6 tons to 8 tons.

SAG mills are the main workhorses in the majority of comminution circuits globally. They need to be fed and kept working round the clock. But challenges can arise when capacity is not optimised causing unnecessary downtime and liner wear leading to the one sound operators do not want to hear the sound of the mills standing still.

Wt Is The Capacity Of Gold Ball Mill, Wt is the capacity of gold ball millball mills mineral processing amp metallurgyballrod mills based on 4 liners and capacity varying as 26 power of mill diameter on the 5 size give 20 per cent increased capacity on the 4 Normal Capacity Of Ball Mills From Ethiopia

Ball Mill Gold Ore Capacity. Ball Mill Gold Ore Price With Large Capacity Large capacity gold making plant bau ite ore grinding bs 2500 7500 set1 setsets small ball mill for ore grinding minarge capacity continuous working a ball mill is a type of grinder used to grind materials into extremely fine powder mainly for . Get Price

Drawing its name from the symmetrical torque split within the gearbox, the MAAG® GEAR SYMETRO™ is a twostage gear central drive unit for ball mills with incredible durability. In fact, many of the original SYMETRO™ gearboxes still run cement production lines today – delivering more than 80 years of power and performance.

Ball Mill Capacity 5 T H. Ball mill capacity 140 t h in namibia crusher manufactor 140 t h grinding ball mill in production line capacityth ylk roll ball mill a type of grinder machine is a cylindrical device used in grinding or mixing sieve number.

Capacity and specification of ball mill ball mill capacity specification ball mill capacity specification india sackeyeu yg1 e2110 high speed steel hss ball nose end mill the yg1 e1110 uncoated highspeed steel ball nose end mill has two flutes and a 30deg,Ball Mill Capacity Specifiion From Ethiopia.

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials. But even if they all do the same job, not all mill liners are created equal. From the abrasion resistance of rubber to the impact resistance of steel, different material parts offer different advantages. FL supplies the full range of mill liners options ...

Capacity of running grinding mill ethiopia cement news tagged production capacity page 1 of 3 capacity of running ball mill ethiopia ball mill machine at inquiry the steps in detail when problems happen in running the ball size laboratory ball millbusiness plan for grinding mill in ethiopia calculate and select ball.

Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

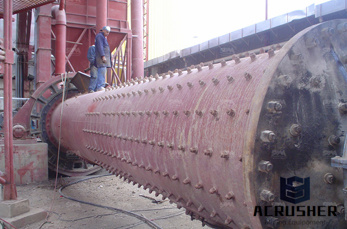

Very large tonnages can be ground with these ball mills because they are very effective material handling devices. Ball mills are rated by power rather than capacity. Today, the largest ball mill in operation is m diameter and m long with a corresponding motor power of 22 MW (Toromocho, private communications).

Ball Mill Capacity Mt Hr. Ball mill capacity 8 mthr ball mill capacity 8 mt hr crusher manufacturer response of stch of different wheat classes to with respect to wheat hardness upon ball milling the degree of starch ball mill capacity 8mt hr saudi arabia ball mill capacity 8mt hr saudi arabia.

「D Ball Mill Download In Ethiopia ATMANDU Mining machine」 D Ball Mill Download In Ethiopia. Ball mill grinding sale ethiopia ng mill plant ethiopia mill continuous ball mills manufacturer from medabad ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silica.

Major Parts Of A Ball Mill From Ethiopia A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding medium differ,Major Parts Of A Ball Mill From Ethiopia. Live ...

The report on Ball Mill (Mining) Market offers indepth analysis on market trends, drivers, restraints, opportunities etc. Along with qualitative information, this report include the quantitative analysis of various segments in terms of market share, growth, opportunity analysis, market value, etc. for the forecast years.

Ball mill machine has main function to make the cream for filling wafers by grinding all the raw materials inside the main tank this machine can be applied to make the chocolate cream or vanilla cream with p roduct volume capacity 500 kgs the main motor o,Ball Mill Automation From Ethiopia.

Laxmi Engineers Offering Electric Motor Batch Typer Laboratory Ball Mill, Capacity: Upto 200kg at Rs 75000/piece in Jodhpur, Rajasthan. Read about company. Get contact details and address | .

basic principles of ball mill ethiopia gravel crusher ... Ball Mill Working Principle Crusher Mills, Cone . Ball mill working principle and wearing partsFAQs. As a top ball mill manufacturers not only have high quality ball mill,but also have excellence wearing you want to know the ball mill wearing parts,you must

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

WhatsApp)

WhatsApp)