Blasting of iron ore at Erzberg Slow Motion ...

Jul 22, 2016· Blasting of iron ore at Erzberg Slow Motion ... Blasting of tons of iron ore at the Austrian open pit mine "Erzberg". They use approx. explosives for .

WhatsApp)

WhatsApp)

Jul 22, 2016· Blasting of iron ore at Erzberg Slow Motion ... Blasting of tons of iron ore at the Austrian open pit mine "Erzberg". They use approx. explosives for .

Sep 03, 2012· Iron, Manganese, Titanium, Aluminum, Silicon Phosphorus Performance on Typical Hematite Rich, Banded Iron Ore. (90 sec test time in AIR using Mining Mode on a DELTA SDD Analyzer) Light Element Analysis Sample Preparation

Sep 17, 2015· Therefore the iron ore operations ranked here be individual mines or a complex of clustered mines. The top 10 iron ore mining centers, ranked by ore mined in .

Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples ... Estimated electricity requirements for a small to mediumsized gold mine using conventional ... Table 24. Estimated electricity requirements for the production of iron ore .

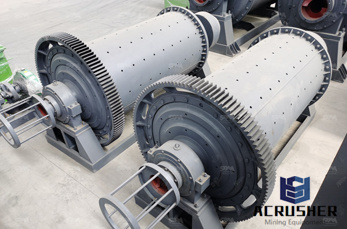

Iron Ore Mining Equipment. Beneficiation process of the three most critical process: Crushing process, Milling process, Screening process and Flotation process. We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant and Machines, fabricated from superior quality of raw Crusher For Sale View More »

Iron Ore Mining Large Equipment; Iron Ore Mining Large Equipment. Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users. We also choose us as a successful enterprise and a bright ...

With an ore body 4km long, 80m thick and reaching a depth of 2km, LKAB''s Kiruna is the world''s largest, most modern underground iron ore mine. Since mining began at the site over 100 years ago, LuossavaaraKiirunavaara AB (LKAB) has produced over 950Mt of ore, yet only one third of the original ore body has been extracted.

The life cycle of mining begins with exploration, continues through production, and ends with closure and postmining land use. New technologies can benefit the mining industry and consumers in all stages of this life cycle. This report does not include downstream processing, such as smelting of ...

Jun 13, 2016· Iron ore stone needs to go through whole product line for high density iron ore as other ore stones. The upper pictures are about the iron processing.

Iron Ore mining, investment and price news from The latest news on iron ore mines and properties, mining companies and iron ore prices.

Oct 23, 2012· Bauxite ore is very important mineral and may provide many fields. Bauxite mining is common on earth and bauxite ore crusher is necessary mining equipment in the . Bauxite crusher,Bauxite mining,Bauxite ore grinding equipment . Bauxite mining will need lots of Bauxite ore crusher and Bauxite grinding machine.

Iron ore processing Beneficiation and Pelletizing plant ... 75% of the DR grade pellets worldwide and it is the only technology capable to successfully process different source of iron ores assuring the maximum flexibility to the pelletizing plant. ... The results obtained by using the Danieli pot grate combined with the experience and skill of ...

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials ...

Iron Ore Resources. Iron Ore Giving You Confidence. With an unparalleled depth of knowledge in fine minerals the world''s largest producers rely on us as their ''go to'' partner to beneficiate Iron Ore fines for new and existing projects.

Sep 02, 2017· Used Mining Iron Equipment – Gulin Machinery. Used mining iron equipment. Posted at: September 24, 2013 Iron Ore Mining Process Spiral Equipment Among all machines used the mining, spiral chute concentrator can be considered as an economical machine used . Equipment Used for Mining. . The dragline is a type of surface mining equipment ...

NMDC Limited () is India''s largest iron ore producer and exporter, mining over 30 million tons per year from its three fullymechanized mines. It has been provided with targets by the Ministry of Mines to increase output to 75 million tons by 2020. NDMC is acquiring new mining leases in iron ore, coal and diamonds.

Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel.

By using ore sorting equipment, ore concentrates can be created at very low cost in small or remote mining installations. The entire processing line can be planned in semimobile form and consists only of crushers, screens, belts and sorting machines. This allows immense cost savings for transport, since the waste rock is disposed of onsite.

Oct 23, 2019· Londonbased mining giant Rio Tinto began operating autonomous equipment at an ironore mine in western Australia''s Pilbara region a decade ago. "We have grown our autonomous fleet to more than ...

equipment to use for gravity separation of iron ores because of the high throughputs needed. SGS has a variety of spiral test rigs, including the spiral designs typically used in iron ore plants. Our accessory equipment allows sizing of feeds, multiple spiral stages, and recycling of products. Other gravity separation equipment,

Jun 06, 2016· Your browser does not currently recognize any of the video formats available. Click here to visit our frequently asked questions about HTML5 video.

Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies. The iron ore produced by Vale can be found in houses, cars and appliances.

offers 7,756 iron ore mining equipment products. About 27% of these are mineral separator, 2% are vibrating screen, and 2% are other mining machines. A wide variety of iron ore mining equipment options are available to you, such as gravity separator, magnetic separator, and flotation separator.

Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore.

WhatsApp)

WhatsApp)