(PDF) Operation and Maintenance of Coal Handling System in ...

yixiang Lang. Transportation machinery equipment in thermal power plant [M].Northeast dianli university book; Application of type comb vibrating screen in coal .

WhatsApp)

WhatsApp)

yixiang Lang. Transportation machinery equipment in thermal power plant [M].Northeast dianli university book; Application of type comb vibrating screen in coal .

Name the four major circuits in steam power plant. Coal and ash circuit ... Proper preparation of coal should be done before feeding the coal to the furnace. In the coal preparation, the coal passes through the different equipments like 1. Crushers 2. ... what is the use of draught in thermal power plants? Draught is defined as a small pressure ...

Find trusted Coal Based Thermal Power Plant supplier and manufacturers that meet your business needs on Exporthub Qualify, evaluate, shortlist and contact Coal Based Thermal Power Plant companies on our free supplier directory and product sourcing platform.

PacifiCorp operates 17 thermal electric facilities that generate electricity from coal, natural gas or geothermal resources. Thermal plants are located in Wyoming, Ut, Arizona, Colorado, Oregon and Montana. PacifiCorp''s power plants use specialized equipment to control environmental emissions and comply with all state and federal requirements.

2 nd type of coal fired power plant are IGCC ( Integrated Gasification Combined Cycle) and these plants have efficiency between 4555% depending on the coal quality and process opted for gasification. Efficiency in a Renewable Energy Power Plant. Hydro power plant has the highest efficiency. The potential head of water is near to turbine so ...

Maintenance of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation costs. Coal handling plants of Thermal Power Generation House have focused on the key measures of Plant study carried of maintenance of CHP,

Coal: In a coal based thermal power plant, coal is transported from coal mines to the generating station. Generally, bituminous coal or brown coal is used as fuel. The coal is stored in either ''dead storage'' or in ''live storage''. Dead storage is generally 40 days backup coal storage which is used when coal supply is unavailable.

The surface condenser is a critical component in the operation of a steam power plant. Condenser failures can result in forced outages and loss of generation capacity. TEi condensers represent an evolution of advanced technology, offering improved thermal efficiency and advanced mechanical design to reduce forced outages and increase availability.

Thermal Plants (Coal, Oil, Gas) For thermal plants, Forney offers a variety of combustion and safety products to help keep your plant up and running. Click on the flame icons for more information on Forney''s products. Fuel Skid. Ammonia Skid. Forney''s burners can be designed for a wide range of heat inputs while providing the flexibility of ...

crushers coal thermal power plant. coal crusher applied for the station boiler station boiler is a boiler providing steam to the turbine generator in thermal power plant, including boiler and ancillary equipment. fuel is burned in the boiler and releases heat energy, and heat transfer through the metal wall of the boiler water into a certain pressure and temperature of get price

Apr 17, 2020· An increase in the share of renewable sources in the energy mix makes coalfired power plants operate in new conditions that require more dynamic operation and adequate flexibility.

Among thermal based power generation, coal based power plants are highest in: Air pollution, Waste generation,Water consumption,Emission of mercury,Greenhouse emission Impact of Thermal power plant on water source Water Intensive New thermal power plant of 500 MW installed capacity requires – around 14 million m3 of water per annum.

Sample 2x50MW Coal Fired Thermal Power Plant Proposal and Quotation. Content . 1. Quotation Remark and Specification. 2. Power plant''s Technical Specification on Main System. 3. Main Schedule of the Implementation. 4. Summary of Quotation. 5. Main List of Power Plant Equipment /P> 1. Quotation Remark and Specification. a. Quotation validity ...

Jan 25, 2018· In a coal based thermal power plant, the initial process in the power generation is "Coal Handling". So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station. ... Equipment used in a coal handling plant 1. Pull chord switch. A series of such switches are ...

Jul 19, 2018· new study into the cost and benefits of installing pollution control equipment in India''s thermal power plants has estimated the bill that the sector will be plastered with at ₹ lakh ...

Apr 23, 2019· Thermal Plant Performance Testing: Gain a thorough understanding of all the performance testing methods for all thermal power plant equipment including boilers, turbines, condensers, pumps, fans, deaerators, and feedwater heaters.; Performance Test Methodology and Code Requirements: Understand the methodology, and code requirements for the performance tests of all thermal power plant equipment

Dec 11, 2017· The sample coal from secondary sampler is finally collected in sampling container and excess coal from secondary sampler is discharges to other plant conveyor through screw conveyor. Work Involve During Preventive Maintenance of Coal Sampling Unit. Check for any spillage. Check the cutter for any wear, tightness and obstructions.

China Cement Producing Equipment Find Detail Coal Fired Thermal Power Plant From CMEC

Mar 15, 2020· In coal thermal power plant, the steam is produced in high pressure in the steam boiler due to burning of fuel (pulverized coal) in boiler furnaces. This steam is further supper heated in a superheater. This superheated steam then enters into the turbine and rotates the turbine blades. The turbine is mechanically so coupled with alternator that its rotor will rotate with the rotation of ...

casing and vessel equipment for nuclear power plants, steelstructures and modular boiler equipment of high readiness. It produces pipeline valves for thermal, nuclear oil gas and chemical industries. Petrozavodskmash is one of the largest machinebuilding enterprises in the Northwest Russia, supplying casing, vessel, tank and other equipment.

equipment suppliers and competition for main plant as well as balance of plant. Several project specific factors like dimensions and orientation of land, quality of inputs, (cooling water, coal), location (coastal/noncoastal) soil seismic conditions etc. make standardization of the entire plant difficult.

In the thermal power plants maximum requirements of fuel is a coal. Coal handling plant (CHP) is the main and major key system to transfer ton of coal fuel to the boiler plant. The handling of this fuel is a great job. The coal has to size, processed, and handled which should be done effectively and efficiently. Because of this CHP management

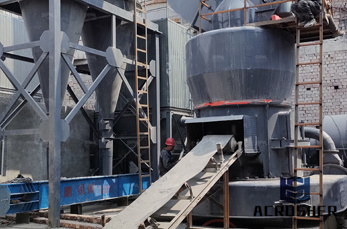

Coal Mill Machine Used For Thermal Power Plant. Why Is A Bowl Coal Mill Used In A Thermal Power Plant. Bowl mills are one type of grinding mill used in a coalfired thermal power plant Raw coal fed into the mills gets converted into pulverised coal and carried to the burners by primary air Secondary air and sometimes tertiary air is admitted also

casing and vessel equipment for nuclear power plants, steelstructures and modular boiler equipment of high readiness. It produces pipeline valves for thermal, nuclear oil gas and chemical industries. Petrozavodskmash is one of the largest machinebuilding enterprises in the Northwest Russia, supplying casing, vessel, tank and other equipment.

WhatsApp)

WhatsApp)