Ball Milling WOODY''S

Ball Mill Nut Wrench Media Separator 1/2" Alumina Milling Media BACK ORDERED 304 Stainless Steel 1/2" 5lb Lead Ball Mill Media 10 lb Lead Ball Mill .

WhatsApp)

WhatsApp)

Ball Mill Nut Wrench Media Separator 1/2" Alumina Milling Media BACK ORDERED 304 Stainless Steel 1/2" 5lb Lead Ball Mill Media 10 lb Lead Ball Mill .

Jul 14, 2020· This video is going to talk about the working principle of ball mill machine.

Ball mills have been used for decades to grind and mix materials used in the ceramic industry. NIDECSHIMPO''s heavyduty ball milling machines enable very precise milling, in porcelain jars, even for relatively tough materials, wet or dry. Here are some main Ball Mill features that can help you in your decision making. PTA01

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill .

A ball mill is a sort of grinder used for grinding, mixing and sometimes mixing products used in procedures of mineral dressing, oils, pyrotechnics, ceramics and selective laser sintering. It operates .

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill .

The ball mill has a low rotation speed, a large media size, and a large radial velocity gradient along the pin. Therefore, the grinding efficiency is lower and the particle size distribution is wide. Therefore, the ball mill is gradually be replaced by the bead mill, and is now only used for .

Ball mills are fine grinders, have horizontal ball mill and vertical ball mill, their cylinders are partially filled with steel balls, manganese balls, or ceramic balls. The material is ground to the required fineness by rotating the cylinder causing friction and impact.

UsedMPT Ball Mill, Type MPT 300. UsedMPT Ball Mill, Type MPT 300. 117" (3000 mm) diameter x 39" (1000 mm) deep milling chamber. Max milling capacity 10 tonnes (10000 kgs) per hr. Corn size 103000 um. Max milling chamber capacity cubic feet ( m3). Max milling speed 24 RPM by a HP/75 Kw, 3Ph/50cycle/380volt motor.

Ball Mill has a wide range of application for suited to process material, where dual operation of grindingcummixing is required. Ball Mill is almost indispensable to Industry manufacturer Paint, Chemical, .

UsedMPT Ball Mill, Type MPT 300. UsedMPT Ball Mill, Type MPT 300. 117" (3000 mm) diameter x 39" (1000 mm) deep milling chamber. Max milling capacity 10 tonnes (10000 kgs) per hr. Corn size 103000 um. Max milling chamber capacity cubic feet ( m3). Max milling .

Mar 10, 2020· How a Ball Mill Works. Ball mills work by using balls to grind materials. Materials such as iron ore, pain and ceramics are added to the ball mill. Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis. As the ball bill rotates, the balls bounce around while striking the enclosed material. The force ...

Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatbased masses. The unique .

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Ball end mills have a rounded nose and create a roundbottomed groove in milling tasks. Also known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill .

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Ball mill and rod mill are suitable for different materials 1. Selection by material''s hardness Ball mill has a strong adaptation of material, and it is suitable for grinding hard materials, such as slag, iron ore, copper ore, etc. Rod mill is suitable for grinding brittle material, such as rare metals. 2. Selection by required particle size

Ball mill fritsch pulverisette working principle. principle of ball mill grinding FRITSCH Planetary Mills: fine grinding of various materials, mixing, homogenising of The Planetary Mono Mill PULVERISETTE 6 classic line is a Working Principle Ball mill .

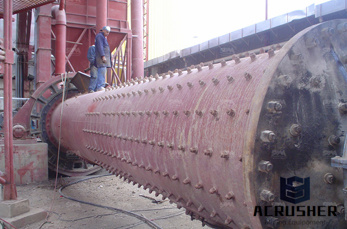

The ball mill is the key equipment to crush the material after being crushed. This type of mill is equipped with a number of steel balls in its cylinder as grinding medium. It is widely used in cement, silicate .

Ball end mills are able to give a contoured profile to molds, dies, and channels. Compared to regular end mills, ball end mills provide a more finished surface and may be used at higher feed rates.

Ball Milling: Ball milling is a grinding technique that uses media to effectively break down pigment agglomerates and aggregates to their primary particles. Using a rotor or disc impeller to create collisions of the grinding media, the impact and force created by the bead mills .

China Ball Mill Machine manufacturers Select 2020 high quality Ball Mill Machine products in best price from certified Chinese Mill Equipment manufacturers, Grinding Mill suppliers, wholesalers and .

Jun 20, 2019· For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 3045%). Pulp (crushed ore and water) fills another 15% of the drum''s volume so that the total ...

WhatsApp)

WhatsApp)