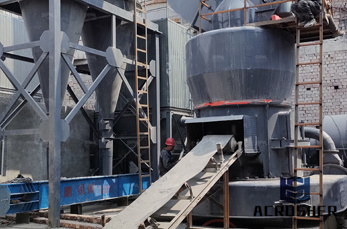

Vertical Roller Mill Structure And Working Principle

WORKING PRINCIPLE The motor drives the grinding table through decelerator. The materials fall down the center of grinding table from feed opening. At the .

WhatsApp)

WhatsApp)

WORKING PRINCIPLE The motor drives the grinding table through decelerator. The materials fall down the center of grinding table from feed opening. At the .

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and grain mills are an alternative to traditional millstone arrangements in mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the ...

Working Principle of Vertical Roller Mill . The raw materials are released and transmitted by the feeding belt conveyor from the raw material hopper, with the weight of the materials being controlled by the belt scale and the tramp iron in the materials being removed by the iron remover. Subsequently, the materials are sent to the elevator, via ...

Environmentfriendly vertical roller mill for mine. From the working principle, the process of the vertical roller mill for mining is that the material passes through the grinding device and is repeatedly rolled into powder by the vertical roller mill for mining. In terms of the .

working process of vertical roller mill. The vertical roller mill used in industry is a kind of roller mill. The basic principle is to place the material to be ground between the grinding roller and the grinding disc, and use mechanical force such as spring force, hydraulic pressure or .

The research report, titled [Global Vertical Roller Mill for Cement Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025], presents a detailed analysis of the drivers and ...

Vertical Roller Mill Working Pdf Vertical Roller Mill Working Pdf. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral .

The vibration control of raw material vertical roller mill system News Date: 14:13:26. The vibration of mill body of vertical roller mill is a normal phenomenon exists in working condition, reasonable vibration is allowed, if the mill has a violent vibration, it will cause damage to millstone, roller lining and accessory equipment. . Therefore, vibration values in working condition ...

Vertical Roller Mill Training by PAI YouTube. 11/2/2017· Vertical Roller Mill Training by PAI This video was made by PAI which introduce the working principle of Vertical Roller mills. : BCC Hardfacing, Wear Plate, Wear Parts/pics/ Vertical Roller Mill Training by PAI YouTube

Vertical Roller Mill Working Principle Of Vertical Roller Mill. A vertical roller mill is a type of industrial equipment used to crush or grind materials into small particles. These machines consist of a large heavyduty steel drum that relies on both hydraulic and pneumatic forces to pulverize rock or stone.

Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by shattered, crushed...

It was concluded that vertical roller mill circuit has an advantage over conventional ball milling circuit in terms of energy consumption. ... Working press. Mroller (bar) 94. 94. Classifier ...

Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

Calcium Carbonate Powder Vertical Roller Grinding Mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Feb 17, 2016· In this training module, we''ll cover the operation of a vertical roller mill. This mill is commonly used in the cement industry in order to grind raw feed. W...

Working definition of vertical roller mill . Vertical Roller MillVerical Roller Mill Types. The basic process is the vertical mill finish grinding but in order to pregrinding and roller presses to compete adapt to the pipe milling system transformation and Japan since 1987 has developed a vertical mill pregrinding system and gradually be developed.

Introduction of Vertical Roller Mill . CLUM Vertical Roller Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types. Working principle of Vertical Roller Mill: The grinding disc is driving by motor through reducer. The material falls to grinding disc from the feed opening.

As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs. The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limited.

With regards to comparing grinding mills; what are the advantages of vertical milling machine compared to conventional ball mill? A more appropriate term is vertical roller mill or VRM for are two different types of vertical mills: Vertical roller mills. Such mills normally have int

Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the ...

Vertical roller mill operation. Since the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following:

Dec 22, 2014· Vertical Roller Mill Working Principle Material through the feed tube fell on the center of vertical roller mill grinding plate, centrifugal force generated from the rotation of grinding plate uniformly scatters and flattens the materials outwards the surrounding area of vertical roller mill grinding plate, to forms a certain thick layer of materials bed, the material was crushed by number of ...

vertical roller mill working pdf. Vertical Roller Mill Introduction Vertical Roller Mill is a new kind of . /5() vertical roller mill working pdf miningbmw. Roller mill Wikipedia, the free encyclopedia. Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or .

vertical roller mill detailed analysis and working principle. vertical roller millworking principle vertical roller mill detailed analysis and working principle Vertical Roller Mill Working Principle Material through the feed tube fell on the center of vertical roller mill grinding plate centrifugal force generated from the rotation of grinding plate uniformly scatters and flattens the ...

WhatsApp)

WhatsApp)