Primitive Technology: Experiment with limestone kiln (CaO ...

Nov 28, 2017· Primitive Technology Experiment with limestone kiln (CaO) is our next video. In this video we put the furnace to burn calcareous lime (CaO). .

WhatsApp)

WhatsApp)

Nov 28, 2017· Primitive Technology Experiment with limestone kiln (CaO) is our next video. In this video we put the furnace to burn calcareous lime (CaO). .

Oct 29, 2019· The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but ...

A concrete made from a mixture of lime, sand, and gravel is said to be as lime concrete. It was widely used before the lime was replaced by Portland cement. Since long, Lime has been used to make things like plaster and mortar. Lime is usually made by burning of ; lime itself is calcium oxide (CaO) and is made by roasting calcite

Process Of The Manufacture Of Cement Using Limestone. How concrete is made material, manufacture,.Natural cement consists Process Of The Manufacture Of Cement Using Limestone mainly of lime, derived from limestone and often combined Concrete made with Portland cement is considered superior to that made with .

The process of calcination derives its name from the Latin calcinare (to burn lime) due to its most common application, the decomposition of calcium carbonate to calcium oxide and carbon dioxide, in order to create product of calcination is usually referred to in general as "calcine", regardless of the actual minerals undergoing thermal treatment.

Limestone. Limestone is a sedimentary rock composed mostly of the mineral calcite and comprising about 15% of the Earth''s sedimentary crust. It is a basic building block of the construction industry (dimension stone) and a chief material from which aggregate, cement, lime and building stone are made. 71% of all crushed stone produced in the is either limestone or dolomite.

the desired chemistry. The process of cement making is, however, remarkably flexible in terms of the raw materials that can be used to achieve required chemical compositions. Many limestone deposits, provided they are low in MgO, easily meet the requirements and a number of other CaOcontaining raw materials are known to be used. Alternative

Concrete is a hardened material that forms when a mixture of cement, sand, crushed stone and water is poured into moulds or formwork and allowed to cure or harden. Cement is made by strongly heating a mixture of limestone, silica and clay in a kiln until small peasized lumps called ''clinker'' form.

Aug 27, 2015· The dry process has been modernized and is widely used at present because of following reasons: Competition: At present, several dry process cement plants are vying with each other. The cement consumers in general and the practicing civil engineers in particular are greatly benefited by such competition.

Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

Aug 12, 2014· So what is portlandlimestone cement? PLC is a slightly modified version of portland cement that improves both the environmental footprint and potentially the basic performance of concrete. It is now described in ASTM and AASHTO specifications and is used just like traditional portland cement in mix designs.

Process Discretion: Wet process, Semidry process, Dry process and Finish process. The environmental im pact of the cement production and its variations between different cement plants, using .

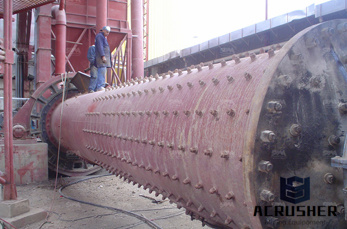

This experience plus the years of manufacturing know how unquestionably qualify Grate Discharge grinding for the Cement Industry. RAW CEMENT GRINDING This phase of grinding may be either the wet or dry process, the end product going to a kiln. Material ground consists of limestone, cement rock, marl or marine shells along with secondary ...

Aug 30, 2012· Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

Jan 29, 2014· How is concrete made from limestone? January 29, 2014 By e3admin. ... It is mixed with water, sand and crushed rock to create concrete. The water, added through a process called hydration, starts the chemical reaction that causes the cement to harden and set, holding all of the ingredients together as concrete. ...

Volume 3, Issue 5, November 2013 ... tradition of using hydraulic cement in structures such as canals, fortresses, harbors, and shipbuilding facilities. The technical knowledge of making hydraulic cement was later century. Modern ... Process of lime stone extraction1.

Limestone rock is a sedimentary rock which forms in the process of sedimentation at the bottom of lakes and oceans, or in caves. It is mainly composed of mineral calcite and aragonite, both of which are crystal forms of calcium carbonate. A limestone with 95 percent or more of calcium carbonate by weight is known as a highcalcium limestone.

Dec 07, 2019· The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but ...

Concrete

Jul 31, 2017· An Attempt at Reproducing Ancient Roman Concrete by using Limestone, Volcanic Ash and Aggregate. See a modern version using Terracotta and red brick in place of volcanic ash https:// ...

Cement is an important construction ingredient produced in virtually all countries. Carbon dioxide (CO2) is a byproduct of a chemical conversion process used in the production of clinker, a component of cement, in which limestone (CaCO3) is converted to lime (CaO). CO2 is also emitted during cement production by fossil fuel

Processing of cement using lime stone. Limestone rock is a sedimentary rock which forms in the process of sedimentation at the bottom of lakes and oceans or in caves It is mainly composed of mineral calcite and aragonite both of which are crystal forms of calcium carbonate A limestone with 95 percent or more of calcium carbonate by weight is ...

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

The production of limestone, or limestone sedimentary naturally drawn to the use of machinery on the soil surface, accounts for more than 10% of total sales in the state, but in terms of the ...

WhatsApp)

WhatsApp)