Metal Casting and Forging Turnkey Specialist, SM Metal ...

4. Outer, Inner and Intermediate Liners. 5. Bolt and Nut. Back to Industry Product Category

WhatsApp)

WhatsApp)

4. Outer, Inner and Intermediate Liners. 5. Bolt and Nut. Back to Industry Product Category

Ball Mill Liner Function Crusher Wear Parts Jys Casting. Ball mill liner function ball mill is a major equipment in the production of power plants cement plants mines chemical industry metallurgy and other industries the liner is one of the components of the mill the .

Optimization of the Cement Ball Mill Operation. ... It is lined with classifyingtype mill shell liners and provided with finer ball charge. Classifying liners ensure that the ball charge is segregated along the length of the chamber keeping larger grinding media at the beginning of the compartment and smaller media towards the end of the chamber.

he smooth liner is easy to roll the steel ball, and the grinding and peeling effect is strong, so the smooth liner is often used in the cylinder of the fine grinding ball mill Liner installation requirements The back end liner and the end cover of the cylinder should be filled with 435MPa cement .

Jul 11, 2015· The liners are damageable parts of cement ball mill. In the working process, liner will be impacted by material constant crushing and grinding, and also by corrosion of pulp. Considering the effects of quality and hardness of mineral, liner, ball and the installation of operating conditions, liner will continue to be worn out and finally damaged.

In many grinding plants mills which have metallic or rubber liners suffer from bolt breakage. Our technicians come across broken mill bolts at many sites around the world, to the operators of the mills it is an almost normal occurrence, but if you have breaking bolts there is an underlying problem which needs to be fixed.

Steel Mill Liners, You can Buy good quality Steel Mill Liners, we are Steel Mill Liners distributor Steel Mill Liners manufacturer from China market. ... High Abrasion CrMo Alloy Steel Mill Liners Wedge Bars for Centre Shell Liners / End Liners. ... High Efficiency Alloy Steel Mill Liners Cement Mill Liners Conch Cement Mill Specification 1 ...

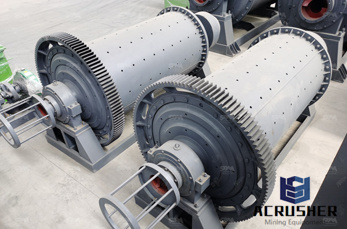

A ball mill is a type of grinder used to grind and blend materials for use in various types of industries. A ball mill works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis.

Nov 18, 2008· Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium ( steel balls) put in the shell, and has a simple structure and ease of handling. Furthermore, The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and wet 14. References 1.

Selection and design of mill liners. ... Liners protect the mill shell from wear and transfer energy to the grinding charge. ... The one of main problem in cement industry is the continouse ...

Calculation of the power draw of dry multicompartment ball mills 225 The mill load that is the volume of charge in the mill is the principal determinant of power draw. Estimation of the ball load that is mixed with the cement charge is difficult and can be highly erroneous. So direct measurement must be taken for calculation of mill load.

Mill shell linings Innovative shape for dynamic grinding movements . The quality of the shell lining is decisive for the production potential of the grinding processes, because the dynamics of the grinding media movement inside the mill is mainly defined by the shape of the mill shell lining.

Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners. Trunnion liners Not many foundries are capable of making trunnion liners.

Shell Liner Assembly For Ore Grinding Mills vajirasriorg. ball mill liner plate assembly prakashpublicschoolin cement mill liner plant assembly ball mill for cement grinding Kiln roller shaft, Kiln shell, .

LINERS MADE TO LAST LONGER IN MINING. Mill liners influences: Milling efficiency ; Mill availability ; AIAE Solution: Based on study of the existing mill operating conditions from maintenance and process point of view, AIAE designs mining liners for ball mills of different stage. single stage, primary, secondary, regrind etc.

Shell Liner Castings For Cement Mill Ball Mill Liners / Ball Mill Chrome Steel Liner, Find Complete Details about Shell Liner Castings For Cement Mill Ball Mill Liners / Ball Mill Chrome Steel Liner,Shell Liner Castings For Cement Mill Ball Mill Liners,Ball Mill Chrome Steel Liner,Sag Mill Liner Plate from Other Fabrication Services Supplier or ManufacturerChengde Rongmao Cast Steel Co., Ltd.

Tube Mill Internals, Shell Liners for Cement Mills AIA Engineering. Bolted shell liners, tube mill internals, boltless shell liners for cement mills from AIA . Grinding efficiency of second chamber maintained at optimum level . Significant reduction in wear rates of balls and the liners .

When lining the shell, start with the odd shaped pieces around the manhole opening if manholes are furnished. Rubber shell liner backing should be used with all cast type rod mills shell liners. If the shell liners are of the step type, they should be assembled with the thin portion, or toe, as the leading edge with respect to rotation of the mill.

Quality High Cr White Iron Shell Liners For Dia42m Cement Mill Liners for sale, Liners Casting Bowl Liners, Cement Mill Liners and HiChrome . grinding mill shell liner elements assetcarecoin. cement mill shell liners erection,Grinding Mill, Shell Liner Castings for Cement Mill DF029 of Ball Mill Liners products for sale from china Shell .

The shell lining in the second compartment or in one compartment finishgrinding mill has special classifiying plate lining and a charge of smaller balls for fine grinding. It .

Manufacturer of High Chrome Castings Cement Mill Liners And Diaphragms, Cement Mill Liners, Mill Liners and Haze Mags Blow Bar offered by Shilpa Alloys Private Limited, Jaipur, Rajasthan.

Aug 06, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Cement Mill Liners, You can Buy good quality Cement Mill Liners, we are Cement Mill Liners distributor Cement Mill Liners manufacturer from China market. Home ... AS2027 NiCr4600 Cement Mill Shell Liner Step Liners Groove Liner Classifying Liner Wave Liners EB5062 Material Grade: 1. Martensitic Cr Mo AlloySteel(ZG50Cr5Mo,ZG60Cr6Mo,Cr12Mo ...

breakage of the mill lining; the x m SAG mills used to shut down frequently Solution • ''s feed head and shell metallic mill lining Results • Higher uptime – the performance of the lining is stable, and the average wear life is extended by 36% • Reduced unexpected downtime • Easier to plan maintenance and repair work

WhatsApp)

WhatsApp)